Champion Concludes Solid State Spark Gap (S3G) Development Program

- September 9, 2016

Champion Concludes Solid State Spark Gap (S3G) Development Program

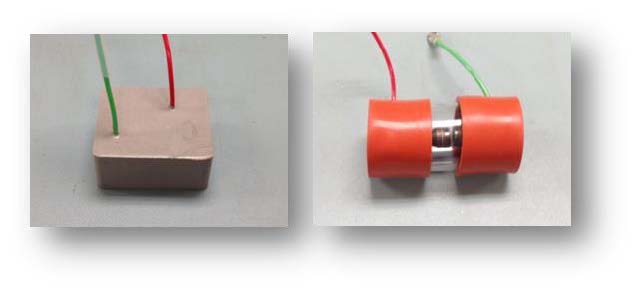

LIBERTY, SC– (September 9, 2016) – Champion concluded a self-funded 205,000 cumulative hour, 1 billion spark Technology Readiness and Reliability Demonstration Program for its Solid State Spark Gap design (S3G)*. The S3G design concept was developed in 2013 as a “Plug and Play” device to replace traditional radiation bearing mechanical Spark Gaps in existing or future designs. The S3G Module is a fully solid state device configurable for highly controlled switching voltages (+/- 2% variance) in a board or single substrate mounted configuration. Traditional radiation bearing Spark Gaps can have +/- 10% switching voltage variance during manufacturing. The S3G module improves system electrical efficiency, life, performance and reliability in an environmentally friendly package. Unlike the radiation bearing traditional mechanical Spark Gap design, the S3G Module has no comparable wear out mechanism. The device utilizes an advanced Champion developed solid state switch that can reliably switch controlled low or high energy discharges (>10 Joule) with minimal heat generation as compared to a traditional Spark Gap. The S3G Module is very similar in size/weight to the traditional Spark Gap and can be potted for optimal thermal and vibration protection for its virtually limitless installed lifetime.

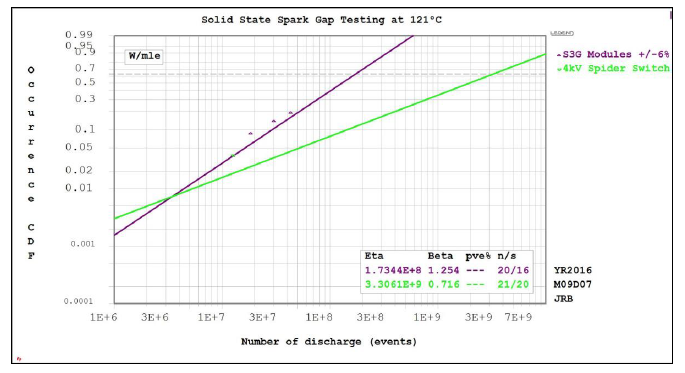

Testing of the highest voltage S3G Module configuration demonstrated a 173 million spark Mean Time to Failure (MTTF) at a continuous environmental temperature of 121°C. This achievement greatly exceeds the MTTF of a traditional Spark Gap design. It should be noted that the 173 million spark MTTF was influenced by Champion defining that the calibrated switching voltage could only vary +/- 6% during the entire test period. A MTTF of 173 million sparks equates to about 24,000 exciter sparking hours or 480,500 engine hours at a 5% duty cycle and a spark rate of 2 sparks per second. Additionally, Champion’s advanced solid state switch, the heart of the S3G Module, demonstrated a MTTF of 3.3 billion sparks. Other key common components of the high voltage output section used within many Champion’s exciter designs also demonstrated MTTFs in excess of 3.3 Billion sparks during the effort. Refer to the Weibull Plot to estimate the Reliability/Unreliability of the S3G for an expected number of discharge events. Champion has already successfully introduced the S3G into Aerospace and Industrial Gas Turbine Ignition System designs.

Champion developed its first solid state ignition systems in the mid-1990s and continues to pioneer highly engineered and reliable solutions for the aerospace industry’s evolving and demanding requirements. Tom Fleetwood, Champion Aerospace’s Director of Engineering noted, “Champion’s engineering strategy recognizes the importance of aligning its technology and product roadmaps to that of its customers to set the conditions for shared achievement of short and long term goals.”

*Patent/Trademark Pending

About Champion Aerospace

Champion Aerospace LLC, a wholly owned subsidiary of TransDigm Group (NYSE:TDG), is a leading global designer, producer and supplier of aircraft ignition system technology and airframe power solutions for use on nearly all commercial, piston and military aircraft in service today. Champion ignition components powered the Wright brothers first powered flight in 1903 and have continued to power the skies ever since.