02

Aug 24

Introducing Champion’s Lightning Series Magneto!

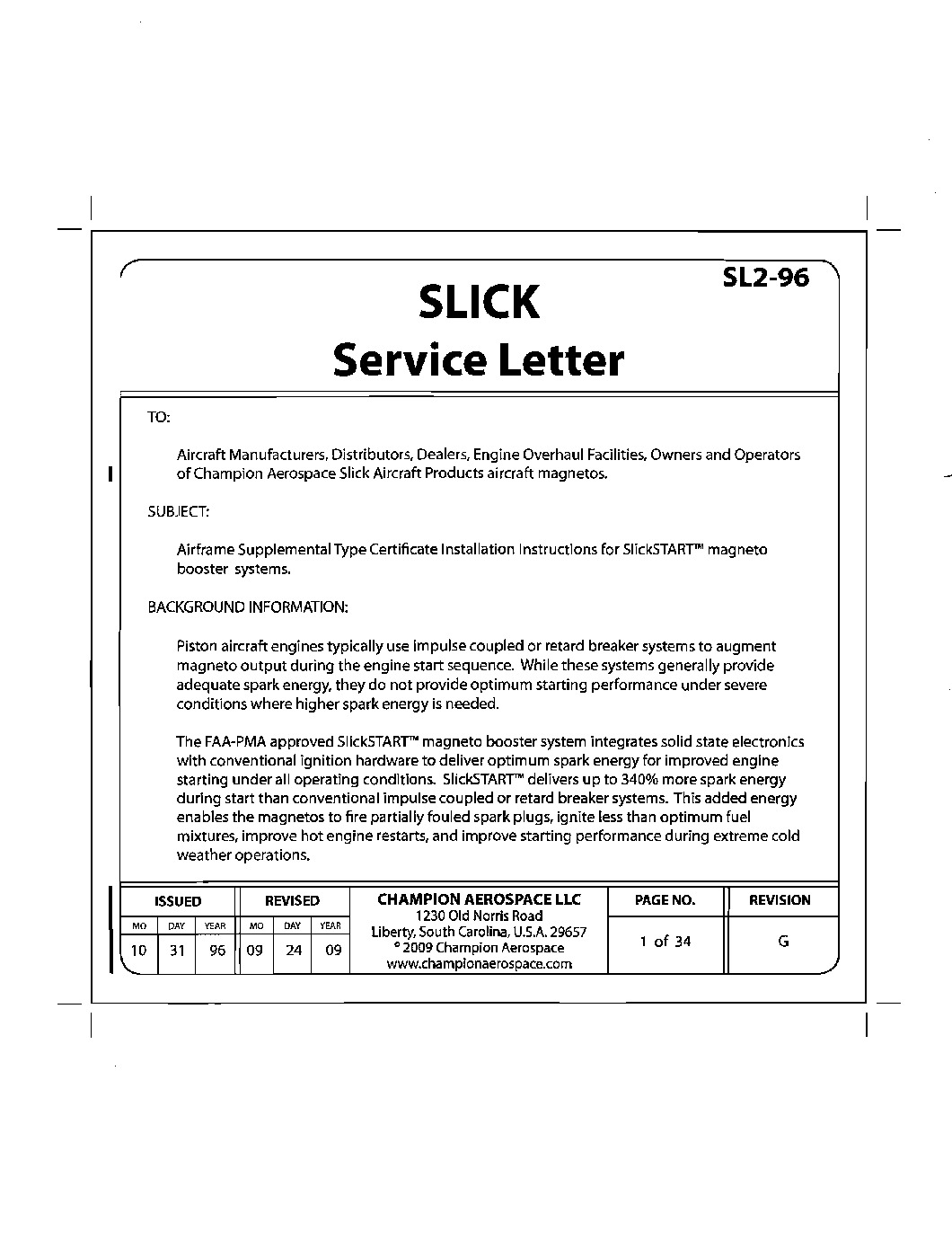

The only fully self-powered, direct replacement magneto utilizing electronic components. Champion’s Lightning Series Magneto requires no maintenance during the time-between overhaul life of a Lycoming or Continental Engine.

Traditional magnetos are highly reliable but have mechanical parts in constant motion that wear over time. Champion’s magnetos have always been engineered so that mechanical parts wear at a balanced rate, however these parts do require regular inspection and maintenance. Champion’s new Lightning Series Magneto has taken the reliability of a traditional magneto and eliminated the mechanical parts subject to wear, reducing any need for inspection and maintenance during an engine’s TBO interval. Traditional magnetos are engine-driven, self-contained units that supply sparks without using an external electric source.

With years of magneto manufacturing and engineering development experience, Champion’s new Lightning Series Magneto remains a highly reliable, engine-driven, self-contained unit that supplies high energy sparks without using any external power source!

Elevate Your Aircraft’s Performance with Champion’s Lightning Series Magneto – No Maintenance Required!

Features

• Lasts for the full 2000+ hour Time-Between- Overhaul Engine Interval

• Generates sparks at 100 RPM using high efficiency electronics

• More energy at 100 RPM than traditional magnetos

• No internal points

• No impulse coupling

• No external power connection needed, even at low RPM

• Proprietary Permanent Magnet design with rare-earth magnets for higher energy output

• Software-free design ensures reliable Circuit Logic

• Direct drop-in replacement, no engine or airframe modifications needed

LOOKING FOR CHAMPION PARTS?

11

May 22

Champion Aerospace is preparing for the age of the More Electric Aircraft (MEA) or All Electric Aircraft (AEA) by transforming its highly pedigreed 28VDC Transformer Rectifier Unit (TRU) to a 270VDC or 540VDC Power Supply system to support operation of new electromechanical equipment that will replace traditional pneumatic or hydraulic power. This operating voltage provides improved electrical efficiency, drives lower aircraft weight, improves aircraft safety/reliability and provides positive environmental impacts. 270VDC is accomplished by rectifying the traditional 3 phase 115VAC 400Hz line-to-line voltages via typical AC-DC conversion methods that meet requirements of MIL-STD-704.

270VDC Power Supply Key Design Parameters:

| Voltage Regulation: | 270 Volts DC (260-280 Volts DC) |

| Min/Max Normal Transients: | 250/280 Volts DC at 40ms |

| Ripple Voltage: | 6 Vpk maximum |

| Cooling: | Self-cooled (Fan or Blast Air) or Free Convection Cooled Versions |

| Power: | 270VDC Typical Range for aircraft applications is 5 to 450 amps; MEA applications could be considerably higher power. |

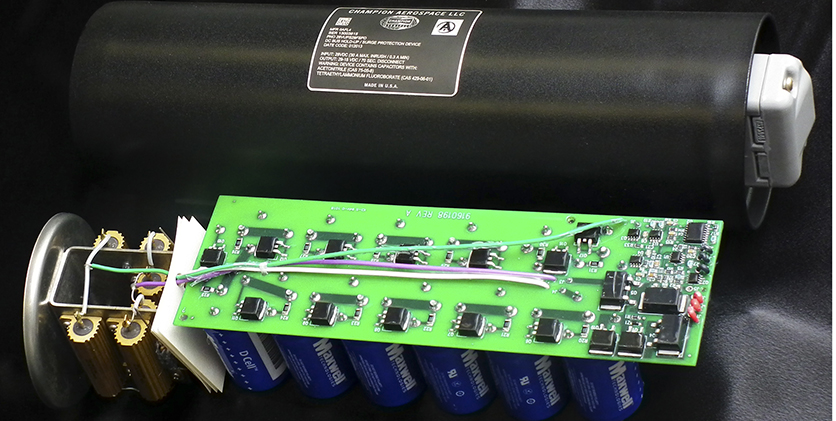

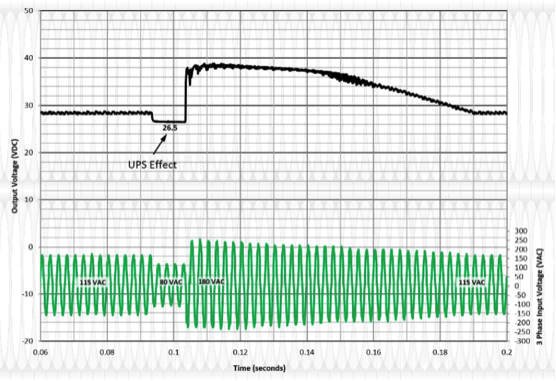

The 270VDC Power Supply may also be used in conjunction with a 270VDC Uninterruptible Power Supply (UPS) attached to the bus for critical mission equipment affected by AC bus transfers, low voltage sags, and other AC/DC interruptions. This allows utilization equipment to maintain full operational capability and “ride through” these interrupts. The device can also provide transient voltage surge suppression during harmful high voltage transients to prevent catastrophic system failures. This UPS device is compatible with all power converters and plays a vital role in preserving the life of utilization equipment.

270VDC UPS Key Design Parameters:

| Output Voltage: | 270 Volts DC (250-280 Volts DC) |

| Cooling: | Self-cooled |

| Disconnect Time: | 70 Seconds |

| Disconnect Voltage: | 230 Volts DC |

Click here to view our distributor list.

LOOKING FOR CHAMPION PARTS?

11

May 22

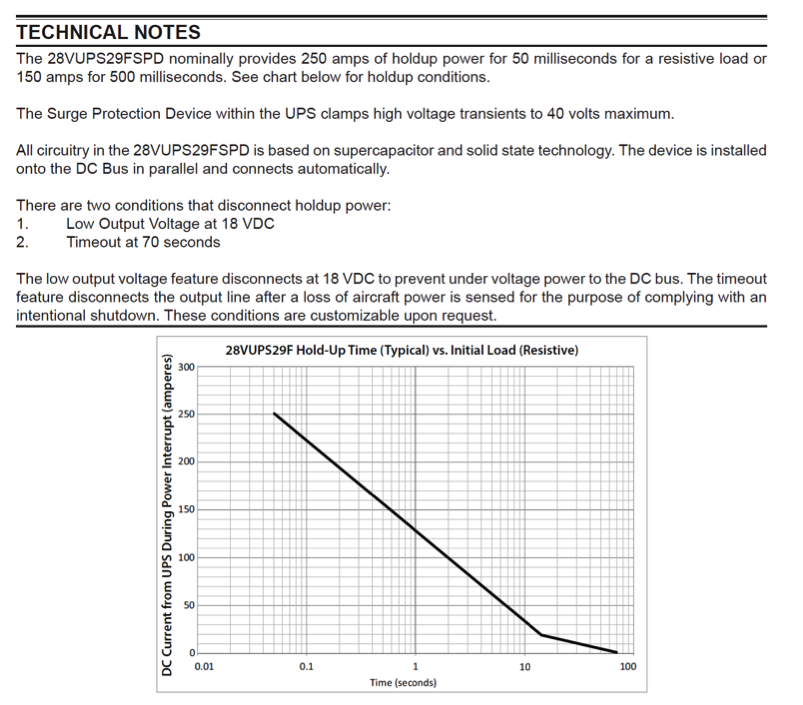

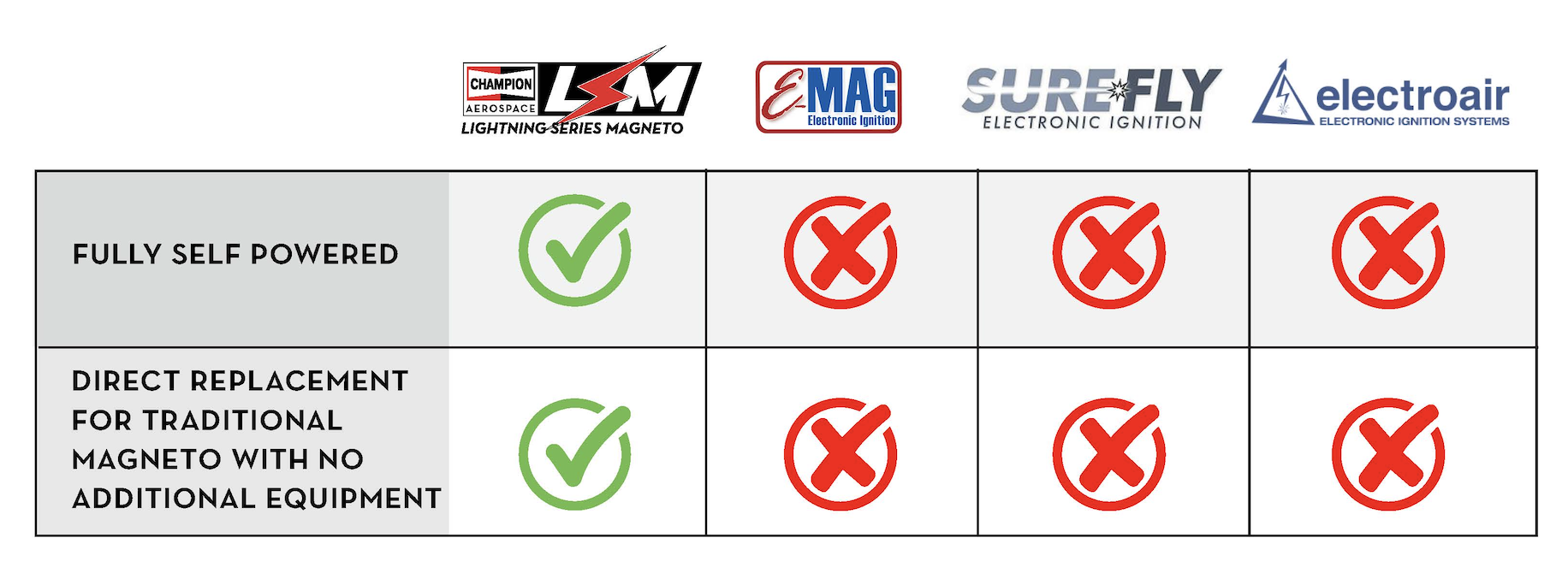

Champion Aerospace Model 28VUPS29FSPD is an uninterruptible power supply with an integrated transient voltage surge suppression (Surge Protection Device (SPD)) circuit specifically designed for airborne applications.

The UPS provides bridge power to mission equipment during AC bus transfers, low voltage sags, and other AC/DC interruptions. This allows utilization equipment to maintain full operational capability and “ride through” these interrupts. The device also provides transient voltage surge suppression during harmful high voltage transients to prevent catastrophic system failures. This UPS device is compatible with all power converters and plays a vital role in preserving the life of utilization equipment. Designed to meet MIL-STD-704 (A-F) for Aircraft Electrical Power, the 28VUPS29FSPD is the latest development of a complete line of uninterruptible power supplies produced by Champion Aerospace, LLC.

| 28 Volts DC Ampere Rating | Part Number | Topology |

|---|---|---|

| 50 | 28VS50Y-12 | TRU |

| 50 | 28VS50Y-30 | PCTRU |

| 100 | 28VS100Y-10C | TRU |

| 120 | 28VS120Y-1, -2, -3, -5 | TRU |

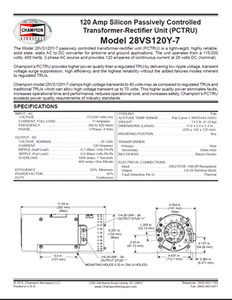

| 120 | 28VS120Y-7 | PCTRU |

| 200 | 28VS200Y-4D | TRU |

| 200 | 28VS200Y-32 | TRU |

| 240 | 28VS240Y-31 | TRU |

| 240 | 28VS240Y-33 | PCTRU |

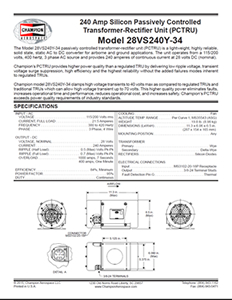

| 240 | 28VS240Y-34 | PCTRU |

| 240 | 28VS240Y-36 | PCTRU |

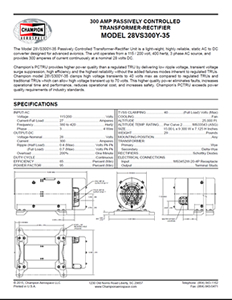

| 300 | 28VS300Y-35 | PCTRU |

Click here to view our distributor list.

LOOKING FOR CHAMPION PARTS?

11

May 22

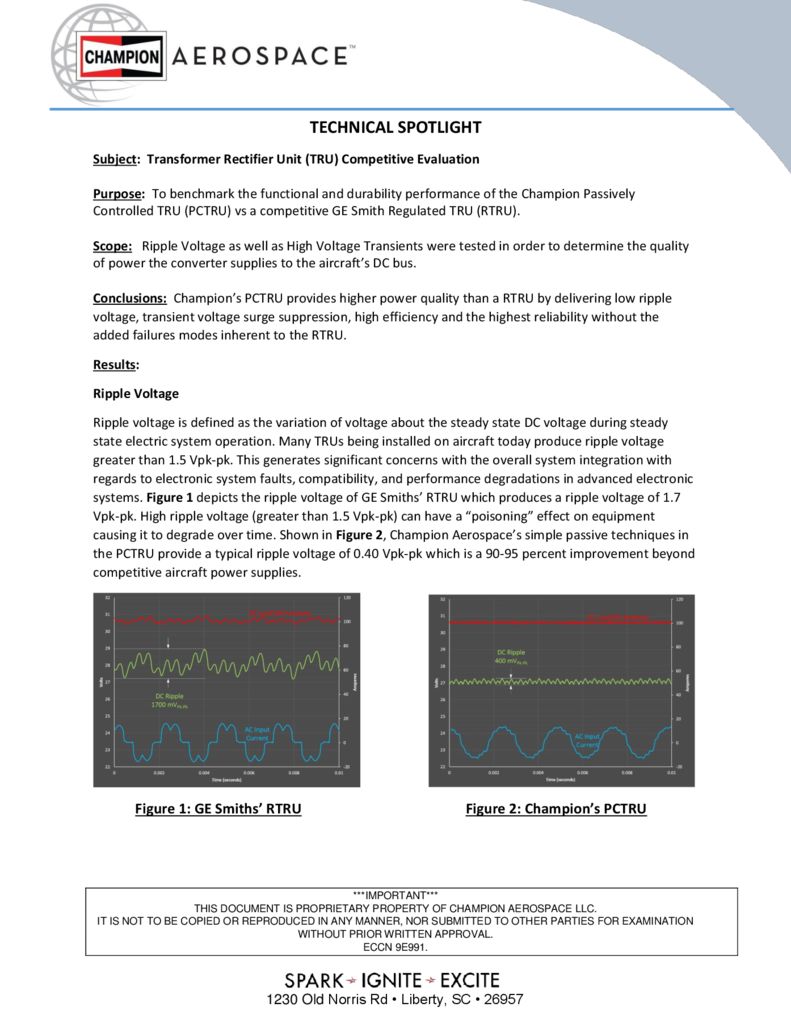

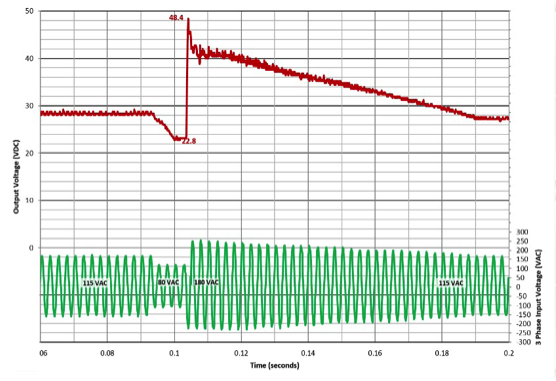

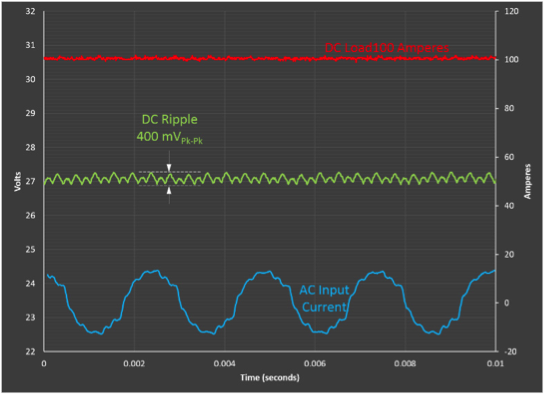

Conventional wisdom says that unregulated TRUs are unable to provide “clean”, low ripple and stabilized voltage whereas regulated TRUs (RTRUs) resolve these concerns with a “tight regulation”, but this is not the case as revealed here. The latest Champion Passively Controlled Transformer Rectifier Units (PCTRU) provide superior voltage stabilization for transients and ripple voltage simultaneously. Data shown here reveals the differences in these converters allowing technical decisions to be made with respect to the different topologies available. The PCTRU is available in existing designs from 50 to 300 amperes.

High Voltage Transients

High voltage transients are generally understood as “life altering events” for utilization equipment containing semiconductor devices. Nearly all advanced electronic utilization equipment contains semiconductors that are susceptible to these high voltage transients. High voltage transients greater than 40 Volts are known to cause equipment to fail catastrophically, and/or prematurely, resulting in the loss of avionics and increasing maintenance costs.

Champion’s PCTRU incorporates transient voltage surge suppression to keep high voltage transients under 40 volts. Champion’s PCTRU suppresses high voltage transients without using active feedback inherent to Regulated TRUs. This transient voltage surge suppression method protects utilization equipment without adding a high steady state failure mode associated with Regulated TRUs.

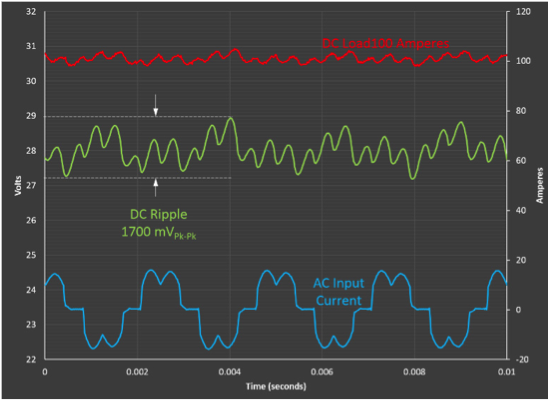

Ripple Voltage

Ripple voltage is defined as the variation of voltage about the steady state DC voltage during steady state electric system operation. Many TRUs being installed on aircraft today produce ripple voltage greater than 1.5Vpk-pk. This generates significant concerns with the overall system integration with regards to electronic system faults, compatibility, and performance degradations in advanced electronic systems. High ripple voltage (greater than 1.5Vpk-pk) can have a “poisoning” effect on equipment causing it to degrade over time.

Champion Aerospace’s simple passive techniques in the PCTRU provide a typical ripple voltage of 0.20 Vpk-pk (shown below) which is a 90-95 percent improvement beyond competitive aircraft power supplies.

Competitive Comparisons

| 28 Volts DC Ampere Rating | Part Number | Topology |

|---|---|---|

| 50 | 28VS50Y-12 | TRU |

| 50 | 28VS50Y-30 | PCTRU |

| 100 | 28VS100Y-10C | TRU |

| 120 | 28VS120Y-1, -2, -3, -5 | TRU |

| 120 | 28VS120Y-7 | PCTRU |

| 200 | 28VS200Y-4D | TRU |

| 200 | 28VS200Y-32 | TRU |

| 240 | 28VS240Y-31 | TRU |

| 240 | 28VS240Y-33 | PCTRU |

| 240 | 28VS240Y-34 | PCTRU |

| 240 | 28VS240Y-36 | PCTRU |

| 300 | 28VS300Y-35 | PCTRU |

Click here to view our distributor list.

LOOKING FOR CHAMPION PARTS?

11

May 22

Champion Tools

The Kell-Strom Tool Co Inc. is the preferred manufacturer of authentic Champion Aerospace Tools. Champion tool inquiries should be directed to Kelstrom Tools at www.kell-strom.com . All tools are sold through authorized Champion Brand distributors.

- Gap Setting Tool 2500A

- Domestic Spark Plug Vibrator Cleaner

- Spark Plug Thread Lubricant

- Crimping Tool

- Abrasive Compound

- Gap Setting Tool CT-415AV

- Spark Plug Tray

- Thread Clean-Out Tool

- Retractable Gap Gauge

- Fine Wire Gap Setting Tool

- Spark Plug Service Unit

- Igniter Erosion Gauge CT-492 (Formerly CT-468)

- Igniter Erosion Gauge CT-494

- Igniter Lead Connector Wear Gauge

- Oil Filter Wrench

- Plug Master Ratchet Wrench (Formerly CT-405)

- Magnetic Spark Plug Socket (Formerly CT-430)

- T Handle Open Box Wrench

- Lead-Master Wrenches

- Oil Filter Can Cutter

11

May 22

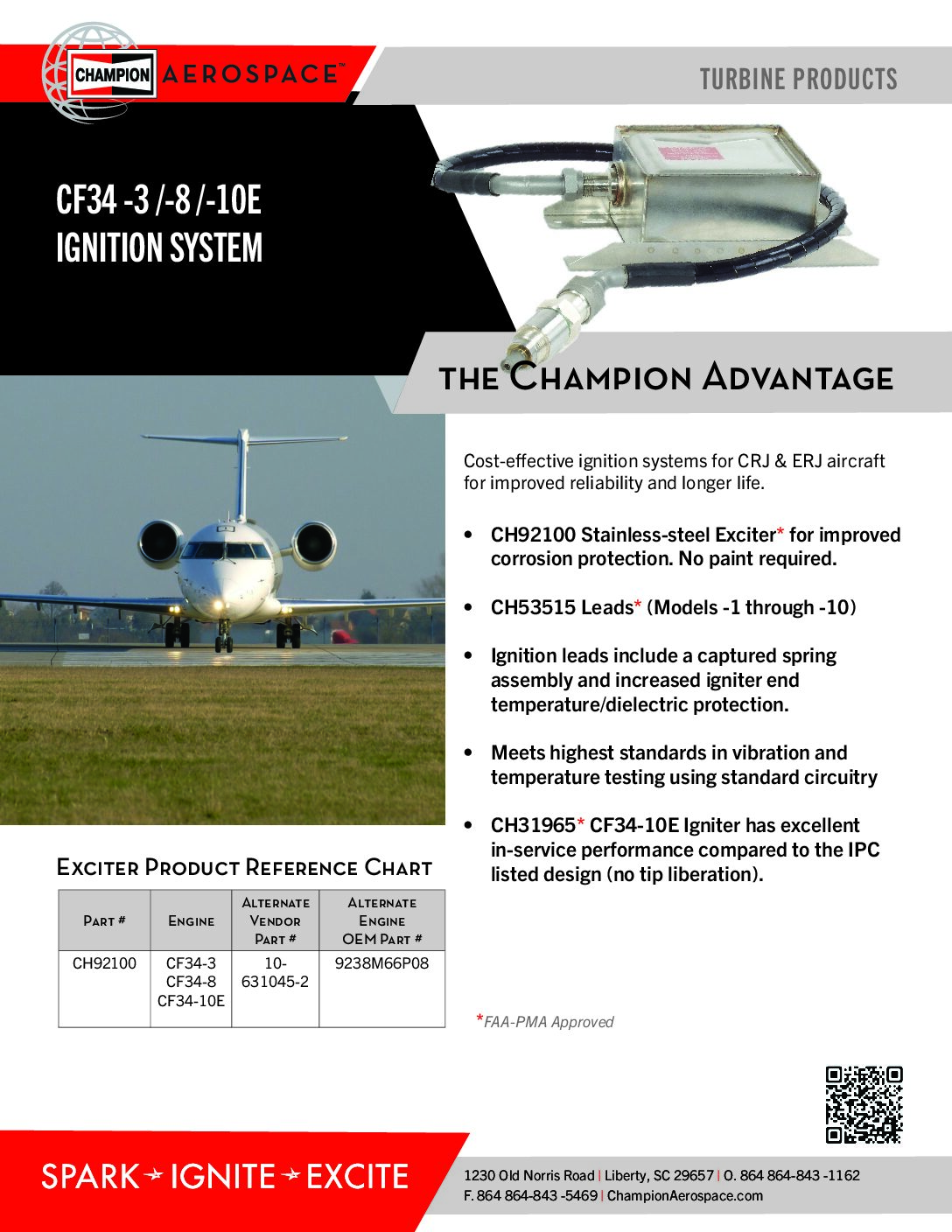

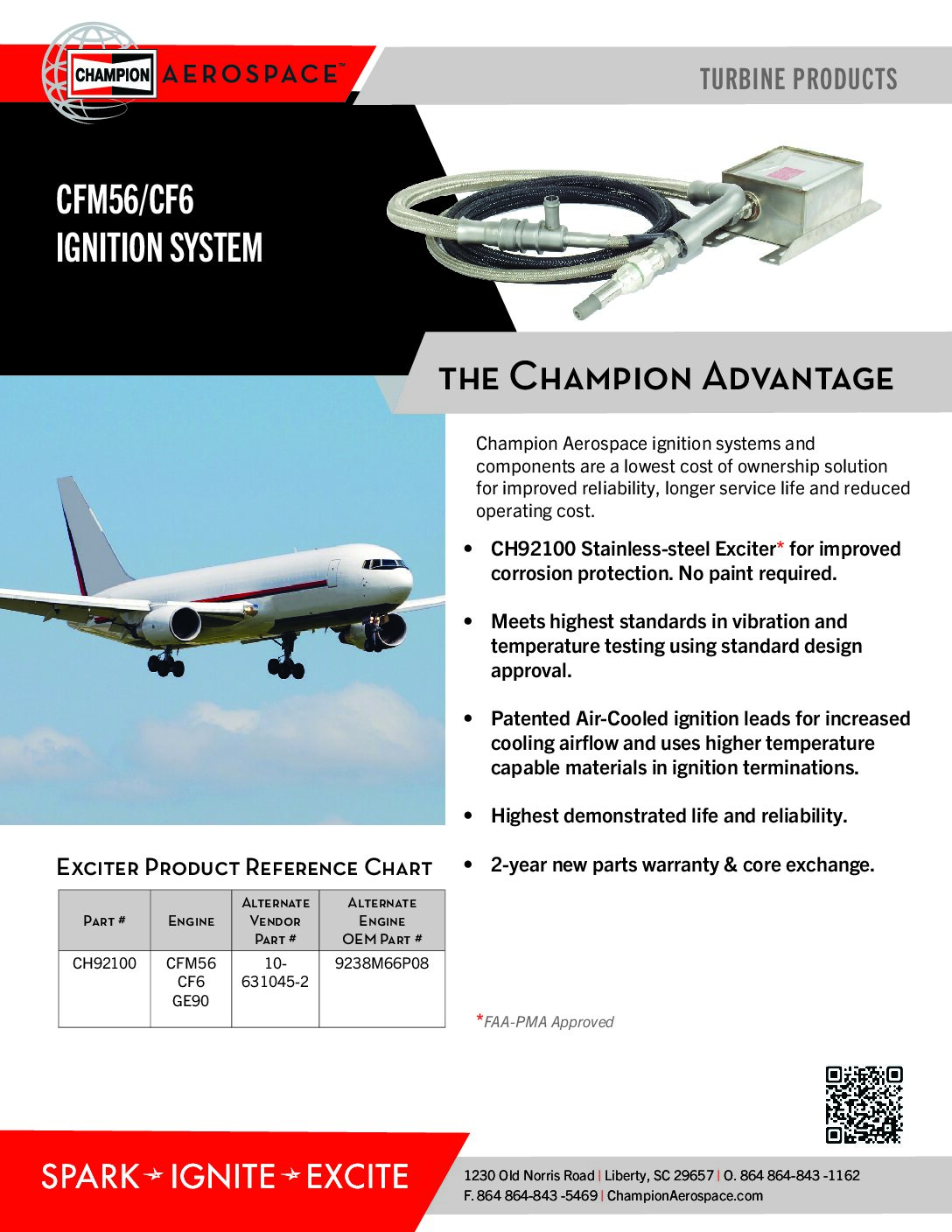

Champion Aerospace is a world leading manufacturer of aerospace ignition systems for turbine engine powered aircraft. With more than 300 different igniter designs, 150 lead designs and more than 50 exciter designs in production, Champion’s ignition system products are specified as original equipment on engines from CFM International, General Electric, General Electric Power & Water, Honeywell, Microturbo , Pratt & Whitney, Pratt & Whitney Canada, Rolls-Royce, Solar, Sundstrand, Siemens, Turbomeca, Volvo, Wesinghouse, and Williams International. Champion Aerospace is also a preferred Tier 1 Ignition System Supplier to Esterline and UTC Aerospace Systems.

There are three components of a turbine engine ignition system: the exciter, the ignition lead, and the igniter. The exciter takes input current from the aircraft electrical system, steps up the voltage, and delivers a high voltage output signal through the ignition lead to the igniter. The igniter sparks once its gap is ionized and the field between the center electrode and igniter shell breaks down. Champion fully supports ignition system design from low to high tension. See Champion’s High-Low Tension Ignition System tech sheet on which type of system is optimal for your engine application. Champion’s ignition systems are optimized to reduce to total cost of ownership for the end user. Many of Champion’s ignition systems incorporate solid state switching technology for maximized performance, reliability, life and environmental considerations (non-radiation bearing exciters).

Champion’s ignition leads are matched to its exciters and igniters to minimize line losses within the system. They offer higher delivered energy than similarly constructed competitive brands, with less flashover and greater electrical shielding. Champion also has ignition lead designs with advance materials to increase the temperature capability above standard industry available solutions. The igniter designs benefit from over 100 years of spark plug and igniter design and manufacturing experience. The result is the longest lasting, most reliable igniter designs in the turbine engine industry.

Champion Aerospace offers ignition systems for military, business, regional and commercial aircraft, featuring long-life igniters, advanced cooled and uncooled ignition leads, and reliable and robust exciter designs. Champion Aerospace also produces ignition systems for the power generation industry to include: land and marine turbines; oil, gas, and coal furnaces; space applications; oil rig operations and pumping stations. The Champion ignition system is a cost effective solution that provides maintainability while improving reliability.

Virtually all components found in Champion Aerospace-brand products are manufactured in our Liberty, South Carolina facility by highly trained and dedicated employees. Champion Aerospace’s in-house innovations and technological advancements have helped prolong component life and reduce maintenance time, cost, and effort. Advanced computerized systems enable its employees to exercise meticulous control over each manufacturing phase throughout the entire operation, including the in-house production of ceramic insulators/semiconductors and machined components, and the assembly of exciters, igniters and leads. Computer aided manufacturing and fabrication processes are designed to meet exacting tolerances, and those specifications are met on every single product. This vertical integration means Champion Aerospace maintains absolute control and is never dependent upon products manufactured to quality standards less demanding than its own. ISO 9001 and AS9101 quality is engineered in every product at every stage of development and production. Through unmatched efforts, numerous patents have been secured for products and systems that make aviation safer and more efficient. All new product development and prototypes are designed, developed and tested in-house to mitigate program risk to the customer.

- OEM and PMA Approved Designs

- High or Low Voltage Designs

- Solid State Ignition Systems for Maximized Performance, Reliability, Life and Environmental Considerations

- Ignition System Kits

- Rigorously Tested and Matched Ignition Systems

- Industrial Hazardous Location Certified Systems for Standard Fuels or Hydrogen

Click here to view Champion Aerospace Product Catalog

Click here to view our distributor list.

LOOKING FOR CHAMPION PARTS?

11

May 22

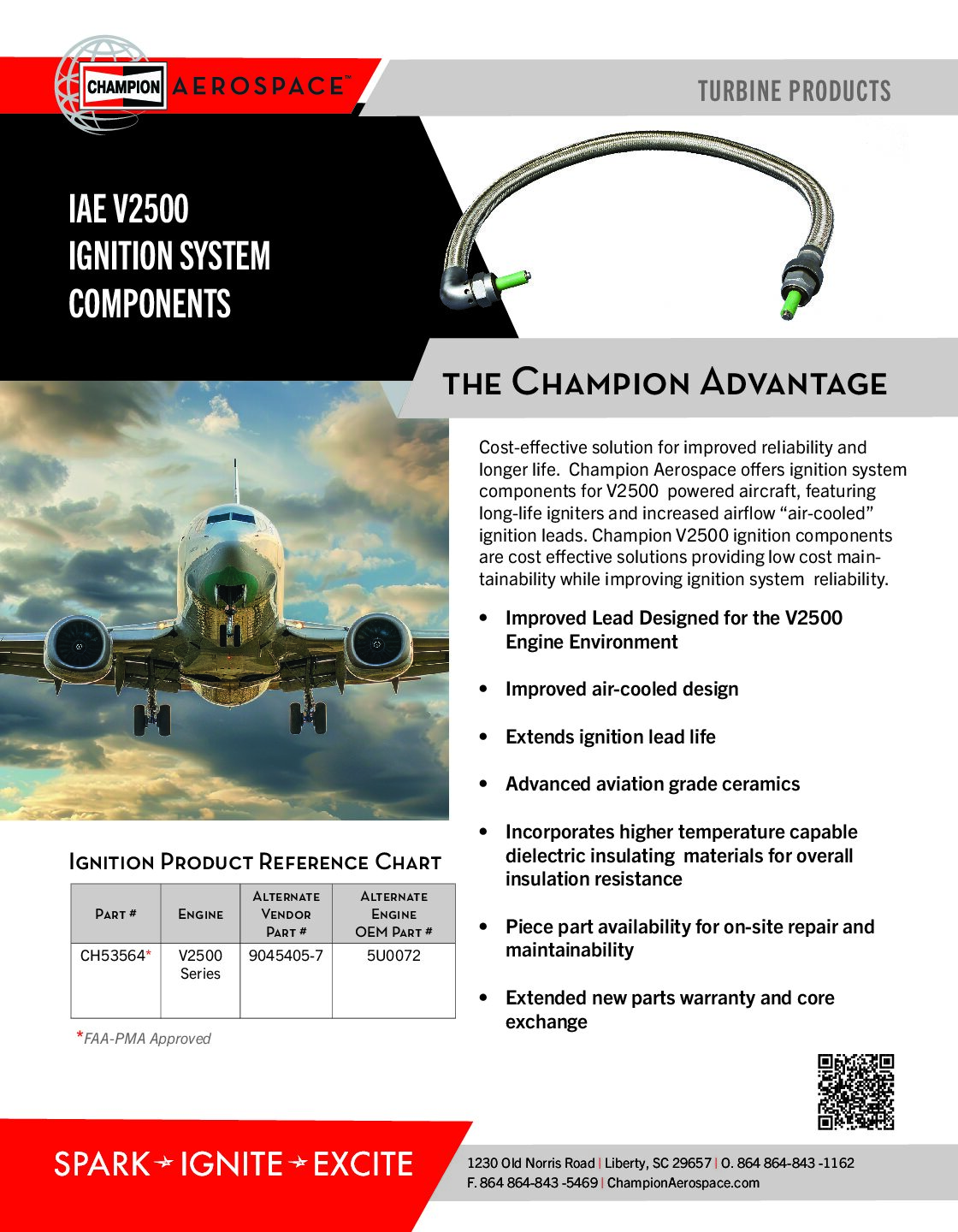

Champion Aerospace designs and manufactures a full range of aerospace ignition leads for turbine engine applications. New ignition leads from Champion Aerospace are available for a wide range of turbine engines, from small turbine APU applications to the large commercial turbofan engines. Notable large commercial engine lead applications include:

- Rolls-Royce Trent 900 (Airbus A380), Trent 1000 (Boeing B787) and Trent XWB (Airbus A350)

- Pratt & Whitney PurePower®, JT-8D, PW2000 and PW4000

- General Electric/CFMI CFM56, CF6, CF34

- IAE V2500

Champion brand leads are designed and constructed to offer the most effective and efficient conduit between the engine exciter and igniter. They offer higher delivered energy than similarly constructed competitive brands, with less flashover, greater shielding, and increased airflow in air-cooled leads. Champion’s air-cooled ignition leads feature patented designs that will assure maximum cooling airflow throughout the service life of the lead and longest on-wing life capability when installed with Champion designed igniters. Champion also provides hazardous Location (HAZLOC) certifications with its ignition systems. Champion has a well-established ignition lead designs that are CSA/ATEX/IECEx certified. These designs can be used as configured or repackaged to meet the any customer specification.

- Contact Assemblies – Material selection provides durable igniter-to-lead and exciter-to-lead interface that resists contact arcing

- Conduit Designs- Material selection to optimize EMI shielding and durability concerns; Champion Patented air-cooled conduit design prevents know competitive design innerbraid collapse that leads to reduced cooling air flow and ultimately thermally degraded components

- Conductor Designs- High Voltage designs utilize MIL-DTL-3702 compliant conductor wire to survive service temperatures up to 450°F (232°C); Low Voltage designs use Champion designed configurations to survive service temperatures up to 572°F (300°C).

- Lengths- Currently support lead lengths from less than 1 foot to 40 feet

Click here to view Champion Aerospace Product Catalog

Click here to view our distributor list.

LOOKING FOR CHAMPION PARTS?

11

May 22

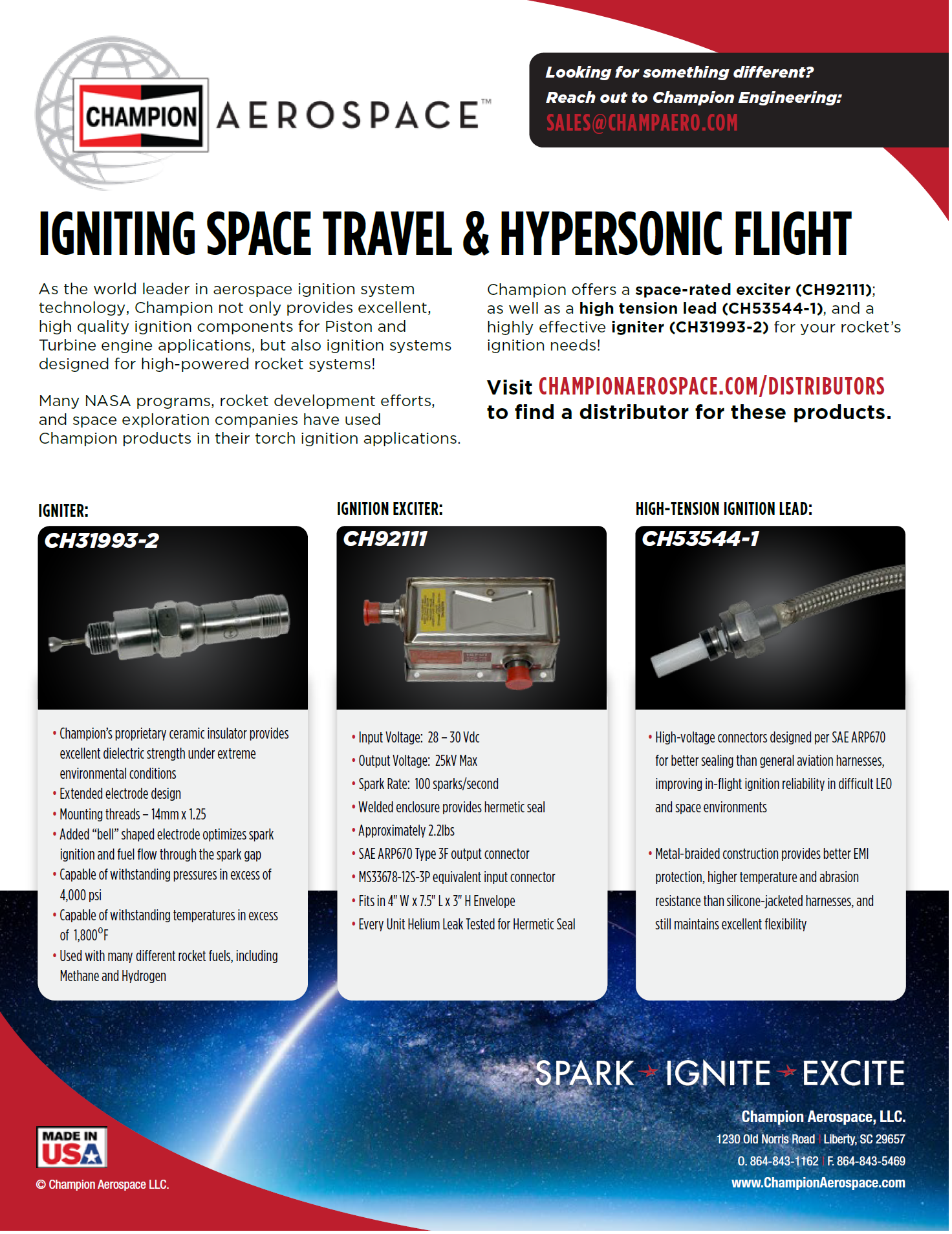

Champion Aerospace manufactures a broad range of high-performance inductive or capacitive discharge ignition exciters in configurable, customer driven designs. Compared to automotive or aviation reciprocating ignition systems, the spark energy discharge of a turbine ignition system is significantly larger- In some cases, the spark is over 100 times higher energy than the spark in an automobile or aviation reciprocating engine.

Champion offers traditional spark gap technology in legacy products, but has transitioned to pioneering designs solely utilizing solid-state technology incorporating our patented multi-voltage “Spider Switch” or new (patent pending) Solid State Spark Gap (S3G) design to maximize reliability, efficiency and capability while minimizing weight. The S3G is a newly introduced concept that is virtually a “plug and play” device into legacy or new applications requiring radiation-free assemblies.

For those customers using radiation bearing exciter designs, note the Champion product is not considered hazardous for use and meets exemptions criteria established by NRC and EURATOM. These exemptions define our exciters are REACH compliant. See Champion Exciter Compliance to NRC-REACH-EURATOM regulatory requirements information paper for further details.

Champion Exciters are widely used in the following aero engine applications:

| Honeywell: | HTF7000*, 131-9 Series, HGT 1700, TPE331, AS907, ALF502, LF507, 331-600 |

| Pratt & Whitney Canada: | PW150*, PW206*, PW307A/B*, PW308A/C/C+*, JT15D, PT6 Series*, PW207*, PW814/815*, APS2300* |

| Pratt & Whitney: | All PurePower® Platforms* |

| Williams: | FJ-44 |

| Rolls-Royce: | Trent 900, Trent 1000, Trent XWB, TP400 |

* Denotes Solid State Configuration

Champion also provides hazardous Location (HAZLOC) certifications with its ignition systems. Champion has a well-established solid state exciter designs that are CSA/ATEX/IECEx certified. These designs can be used as configured or repackaged to meet the any customer specification.

Product Highlight- Pratt & Whitney Canada PT6 Exciter

Champion designed and manufactures the OEM select exciter for the largest turbine fleet in the aerospace industry. The Champion CH92106-1 PT6 exciter, utilizing two fully redundant ignition channels, is able to offer a lighter weight, higher energy, easily reparable and more reliable solution than is offered with the competitor’s exciter. The solid-state switch that discharges the spark event is designed with the latest solid state technology and is not a life limited component like the competitive unit radioactive spark gap.

Champion CH92106-1 exciter benefits include:

- Higher spark rate for reliable starts under all conditions (a 3-spark per second solid state ignition system compared with the current 1-spark per second for 10-381550-4)

- 1.2 joules of energy per second to light the engine (compared to 0.7 joule per second for 10-381550-4)

- Tested in 2009 to the current OEM temperature and vibration requirements

- Non-Radiation bearing exciter; solid state components provide the energy (no spark gap)

- Painted with high temperature paint for corrosion protection

- Un-potted design for improved reparability

The unit has FAA-PMA approval based on Identicality and it carries an OEM part number on the label (3043937-04).

Champion Aerospace manufactures ignition exciters, some of which contain a small amount of radioactive Tritium gas in the high voltage-switching component (referred to in this document as a “Spark Gap”). Spark gaps have been used in turbine engine ignition systems on aircraft since the 1940s, and are simple and reliable high voltage switches. They do require a small dose of radioactive gas in their construction. The fundamental issue is that a radioactive isotope is required to maintain a consistent spark gap ionization voltage over the unit’s operating life. Without the small amount of tritium gas in the spark gap, the ionization voltage of the gap can vary significantly over time and result in a potential decrease in the delivered energy of the exciter. There is no alternative material that Champion can propose for use in our spark gaps that is more benign that Tritium. Competitive comparative spark gaps utilize the less environmentally friendly Kr-85 isotope.

Although the basic elements of every gas turbine ignition system are the same, even the sophisticated observer has trouble delineating amongst the various types. Actual performance, design types, and the physical appearances of most turbine-powered aircraft ignition systems differ from application to application. Engine operational requirements, combustor designs and performance parameters, operating environments, mounting considerations, FAA requirements, and differing design philosophies associated with providing reliable ignition are just a few of the reasons for the many models of turbine engine ignition systems in service today.

Champion Quality and Reliability.

Every Champion Aerospace exciter carries our full warranty and is backed by the Champion name. Our exciters are built to the same exacting standards that have made us a leader in aviation products for over 75 years.

Though more reliable, today’s turbine ignition systems are also more complex, requiring that aircraft technicians possess a higher degree of knowledge and understanding of turbine ignition system theory. Familiarity with a few basics will enable technicians to develop proper insight into standard operation, troubleshooting, and maintenance practices.

Champion offers repair, recertification and overhaul of exciters through our FAA certified repair station. For more information on exciter repairs, please contact your Champion distributor.

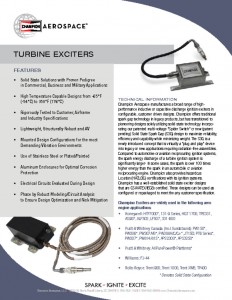

- Solid State Solutions with Proven Pedigree in Commercial, Business and Military Applications

- High Temperature Capable Designs from -65°F (-54°C) to 350°F (176°C)

- Rigorously Tested to Customer, Airframe and Industry Specifications

- Lightweight, Structurally Robust and AV Mounted Design Configurations for the Most Demanding Vibration Environments

- Use of Stainless Steel or Plated/Painted Aluminum Enclosures for Optimal Corrosion Protection

- Electrical Circuits Evaluated During Design Phase by Robust Modeling/Circuit Analysis to Ensure Design Optimization and Risk Mitigation

Click here to view Champion Aerospace Product Catalog

Click here to view our distributor list.

LOOKING FOR CHAMPION PARTS?

11

May 22

Champion Aerospace is a leading supplier to the OEM turbine engine market for airline, business aviation, general aviation, space and military aircraft applications. Champion Aerospace has produced igniter designs for global customers, including land and marine power plants; oil, gas, and coal furnaces; oil rig operations; and pumping stations. Champion can provide Industry certification compliant hardware for hazardous environment requirements (i.e. CSA, CE, ATEX etc…) Plus, it builds more gas turbine igniter models than all other manufacturers combined.

Champion-engineered safety retention features and long-life capable designs are the best in the business. Champion developments to extend life in the turbine igniter design include optimized use of precious metals, super alloys, coatings, air-cooled tip designs, fuel drain slots (which keep the igniter from quenching) and high temperature sealing features to survive today’s extreme combustor conditions. Champion also uses engobe semi-conductive/solid body semiconductor materials for more reliable response to difficult starting conditions.

Champion’s unmatched internal Ceramic Manufacturing capability permits design and manufacture of industry leading Alumina Oxide insulators and Silicon Carbide semiconductors which sets it apart from the competition in product performance, quality and response time.

- Silver-plated shell for protection against corrosion and seizing at mechanical interfaces.

- Advanced glass and mechanical sealing features design outside the combustor case for protection against gas leakage under high temperature conditions.

- Internal configuration designs that optimize heat flow away from terminations to protection sensitive ignition lead components

- Internal termination protective coating to prevent lead component seizing

- Firing end design configurations that can deliver igniter life up to 5,000 flight cycles in select applications

- Use of external wear and thermal barrier coatings to protect the life limiting features from wear and thermal distress

- Option for three different semiconductor bodies for low voltage application requirements

Click here to view Champion Aerospace Product Catalog

Click here to view our distributor list.

LOOKING FOR CHAMPION PARTS?

24

Mar 20

At Champion Aerospace, we are always looking for innovative designs and products to enhance the performance of your aircrafts ignition system. Add SureSTART Ignition Boosters to our list of high performance ignition products. SureSTART provides up to 340% more starting energy to boost magneto output for improved:

- Hot Starts

- Cold Starts

- Flooded Starts

- Normal Starts

STC approved for 99% of all general aviation aircraft, SureSTART has been designed and tested to work in conjunction with conventional magneto systems. SureSTART does not affect the procedures or intervals for inspection, maintenance or overhaul of the magnetos and harness with which it interfaces.

With the exception of a noticeable improvement in engine starting, SureSTART operation is transparent to the aircraft owner/pilot. Requiring less than an hour to install, no modifications to the aircraft flight manual or engine starting procedures are required.

“Every fuel injected engine should have one of these” – SureSTART Customer (Lake Amphibian)

- 1

- 2